Our Products

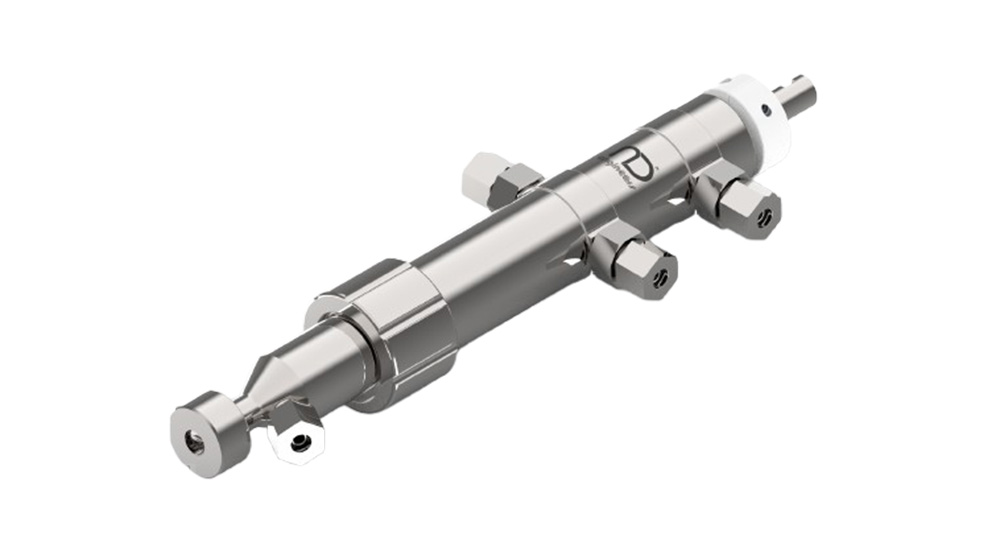

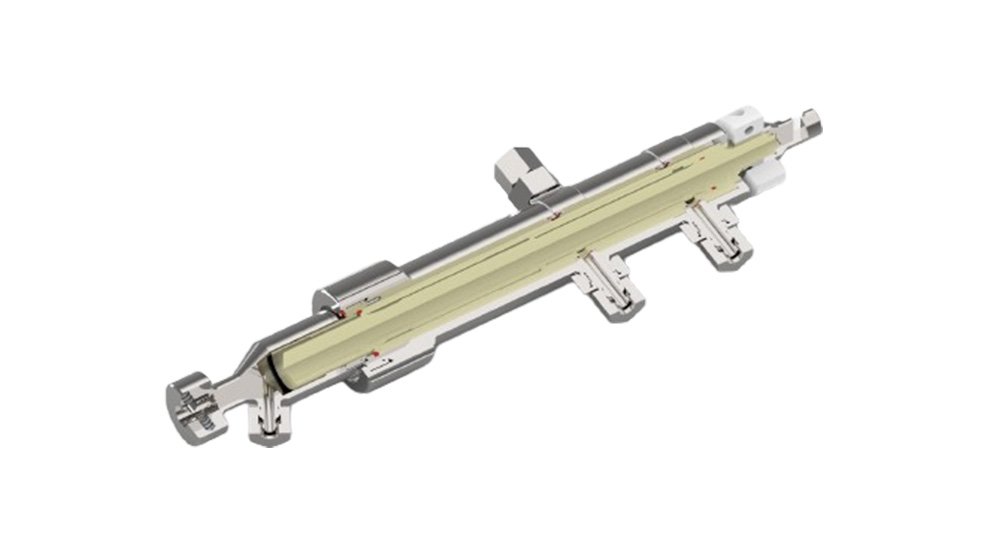

CIP – SIP CERAMIC PUMP

CIP (Clean-in-Place) and SIP (Sterilize-in-Place) are automated processes used in industries like pharmaceuticals and food & beverage to clean and sterilize equipment without disassembly, ensuring hygiene and safety.

Clean-In-Place (CIP):

- Purpose: CIP is a method of cleaning process equipment (pipes, tanks, etc.) without manual disassembly, using a combination of cleaning agents, temperature, and water flow.

- Benefits: Time-efficient, consistent cleaning, reduced risk of human error, and improved safety.

- Industries: Pharmaceuticals, Dairy, beverages, food processing.

Sterilize-In-Place (SIP):

- Purpose: SIP extends the CIP process by sterilizing the equipment using steam or other sterilizing agents, ensuring a sterile environment.

- Process:

- Heat Up: The system is heated to a specific temperature.

- Hold or Exposure: The system is held at the sterilization temperature for a specific time.

- Cool Down: The system is cooled down to a safe temperature.

- Benefits: Ensures sterility, crucial in industries where sterility is essential like pharmaceuticals and biotechnology.

- Industries: Pharmaceuticals, biotechnology, and other industries requiring strict hygiene.